The Pioneering Hide, Skin and Leather Industries of Brisbane: The Dixon Tanneries [Part 2]

By Dr Robin Trotter - 2024 Queensland Business Leaders Hall of Fame Fellow | 25 July 2024

Dr Robin Trotter, 2021 and 2024 Queensland Business Leaders Hall of Fame Fellow

T.C. Dixon & Sons Tannery, Hill End

British born Thomas Coar Dixon (1845–1909) arrived in New South Wales in 1866. We don’t know when he started up in the skin trades in the colony but prior to coming to Brisbane around 1868 he had been operating a small tannery in Moruya, New South Wales. His older brother, Joseph Dixon, who arrived in Australia two years before Thomas, had already moved from New South Wales and taken up land in the Sunshine Coast area – firstly going into sugar cane and then moving into farming.[1] He urged Thomas to move his tannery business north. Thomas did move and started a tannery In South Brisbane (at the corner of Russell and Grey Streets). A short time later he acquired land at 439 Montague Road and in 1873 he built a new tannery on this site close to the Brisbane River.

In a talk he presented in 1908 (on the occasion of the opening of his new boot factory on Montague Road), Thomas Dixon related how he had come to Brisbane and selected the site for his tannery:

I got the place cheap and started the Tannery in a small way. Hill End was very different in those good old days. There were only seven houses on the side of the hill and we were free of all taxes. It was a beautiful place, all the hills being covered in bush.[2]

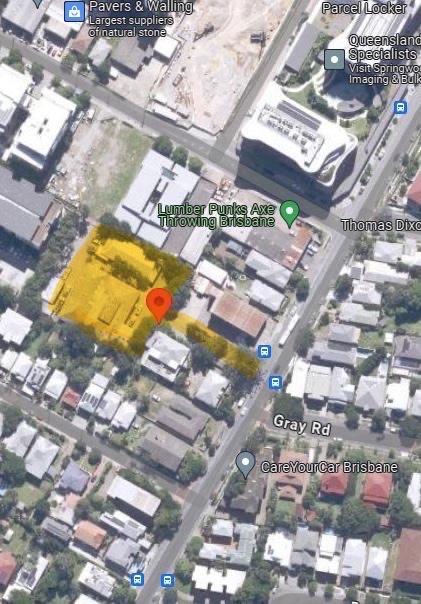

The site Dixon selected comprised 5 acres of river front land. He would have leased this initially because although he started up the tannery in 1873, he did not purchase the land until 1875.[3] The location was perfect for a tannery: well enough away from the commercial and residential areas, it was on the banks of the Brisbane River which provided a good source of water for the tanning processes (and for disposal of waste from the tanning process). The map below shows the site of the tannery today – off Montague Road, between Ferry and Forbes Streets, West End, and the next image shows the front door of the boot factory with the start date of Dixon’s enterprise – 1873

Dixon’s Tannery (former), Photo courtesy of Google Maps.

Front Door, T.C. Dixon factory building, Montague Road, West End, c.2008, Image courtesy of Queensland Ballet.

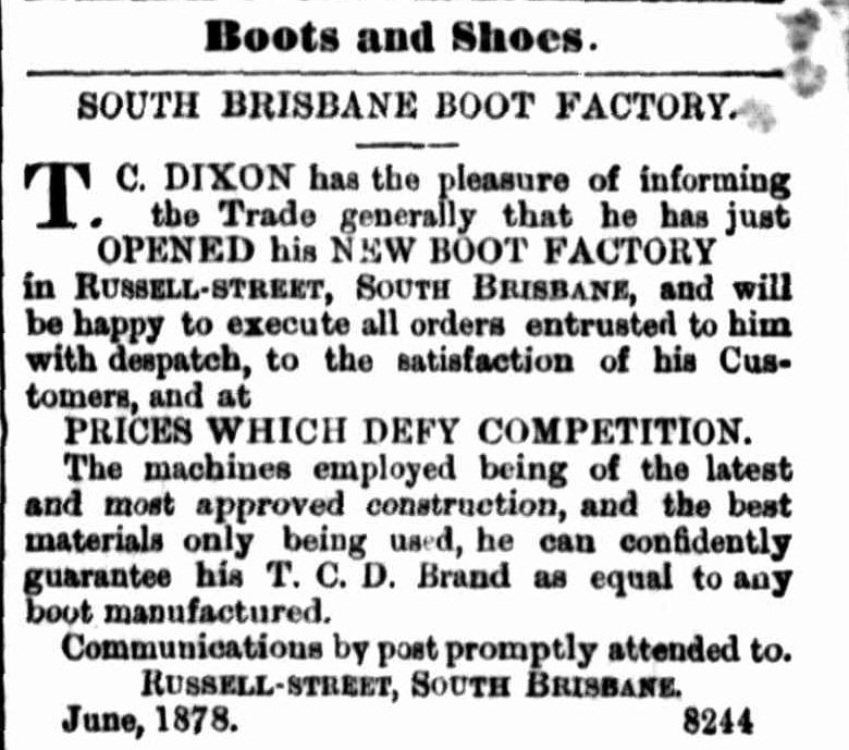

In following years, TCD added more land to his original Montague Road acquisition. In 1878 Dixon moved into turning his leather into boots, first opening a shoe and boot factory at the Russell Street premises which he must have maintained over the years.

The Brisbane Courier, Saturday 22 June 1878, pg1. Image courtesy of Trove, National Library of Australia.

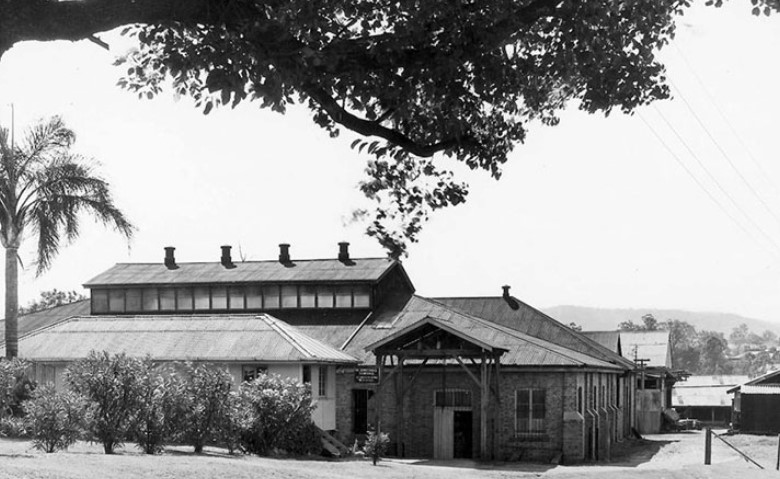

In 1878 he also built a second tannery on Montague Road (image below). Fire, in 1885, destroyed all his West End buildings and just as they were replaced, they were destroyed again in the 1893 flood. Undeterred, Dixon replaced the tannery with a substantial building in 1893.[4]

Early photograph of the Dixon factory. Image courtesy of Jocelyn Dixon.

A report in the Brisbane Courier in 1931 noted that T C Dixon Tannery’s initial business had been the production of ‘sole and harness leathers’, however, in 1902 Dixon had expanded into producing chrome, upper-leathers, such as wallaby, kangaroo, calf, and kid and by that date (1931) it was reported that: ‘Dixon's wallaby is known in all States and other countries. In a season the firm has turned out as many as 15,000 dozen skins per week’.[5]

The next major development by Dixon was the construction of a substantial new boot factory on Montague Road, but on the north side, between Raven and Duke Streets. Completed in 1908, the factory was designed by prominent Brisbane Architect, Richard Gailey. The new factory became the jewel in Dixon’s crown – a boot manufacturing operation that would become, at one point, one of the largest in Australia. The tannery was a critical feature of the whole boot making business, providing the raw material for the shoes and boots produced in the factory, and as such, it continued to operate up until 1970. The boot factory at Montague Road continued for another three years before closure and transfer of the factory to a new location in Wacol where it operated for another seven years, closing finally, in 1980.

I will explore the story of the boot factory in another blog.

The image below shows workers at T C Dixon’s factory. The hide being displayed is a sheep skin, reports expert tanner, Lindsay Packer.[6]

Thomas Dixon’s staff of Tannery workers c1900 displayng a hide. Image courtesy of TC Dixon’s descendent, Kerry Viksne.

Despite fire (1865), and flood (1893), the tannery was rebuilt on several occasions and continued to service what was to become the core business of T C Dixon & Sons, the boot manufacturing factory.

At that 1908 talk Thomas Dixon asserted that the quality of his boots was a product of the quality of his leather:

… like the house that is built on the rock, it stands; but the house that is built on the sand, it falls. It is the quality of the sole leather.[7]

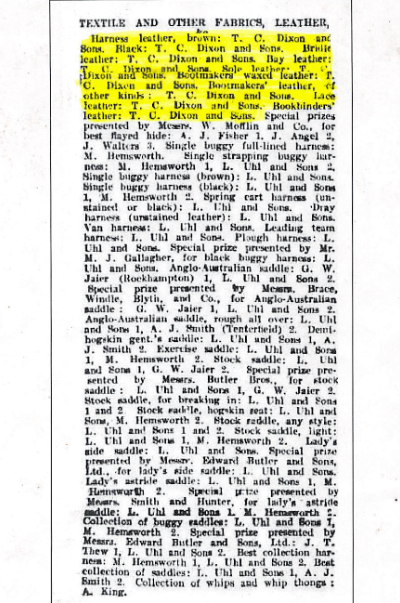

And those were not empty words. The next year T C Dixon & Sons took out a number of awards or their leathers at the 1909 Jubilee Exhibition:

Queenslander, Saturday 21 August 1909, pg45. Image courtesy of Trove, National Library of Australia.

The Week. Friday 20 August 1909, page 12(2). Image courtesy of National Library of Australia.

The image below is the Dixon Tannery constructed in 1893 to replace the building lost in the flood of that year. According to the Brisbane City Council Heritage Citation, the new tannery contained a suction 42 hp gas engine and two storerooms, As late as the 1950s the building underwent modification with a waste discharge system, stoppage sheds and drying racks. Finally, when it closed in 1970 it was no longer viable.[8]

Dixon Tannery, c.1970. Image courtesy of Jocelyn Dixon.

After closure of the Tannery, the property changed hands several times. This year (2024) saw a new proposal for a multi-story apartment block on the tannery site with a promise that the project will preserve the original 19th century heritage listed tannery building.

Artist’s impression of ‘The Tannery Residences’. Photo courtesy of Cottee Parker

Donald Dixon Industries LTD, Hemmant

The second Dixon tannery we now turn to is that of Donald Dixon’s Tannery. For this, we need a brief excursion into family history. Two of Thomas Coar Dixon’s sons were entrusted with the management of his two ventures: the Boot Factory and the Tannery. William Victor went into the Tannery and his brother, Ernest Joseph, went into the Boot Factory. We now follow William Victor and his son, Donald Coar Dixon. Donald worked in the Tannery under his father and learned his trade. Family historian, Douglas Kesteven (and son-in-law of Donald Dixon), recalls: ‘Don would often say he grew up with tanning liquor in his blood’. Donald enlisted in WWII, served first in the RAAF before being seconded to the RAF. On returning home after the war, he returned to the West End Tannery for a short period before leaving in the early 1950s to start his own tannery in Fleming Road, Hemmant, in the Redlands area.[9]

By the early 1950s, the Donald Dixon tannery was in full operation. By the early 1960s, the tannery was employing about 400 people. And, by the 1980s the company had opened a new factory in Toowoomba to handle the initial tanning process whilst the Hemmant plant continued to dye, condition and apply the finishing coats to the product. However, despite the Toowoomba plant operating well, the Donald Dixon Industries venture was facing problems. The loss of key people, ill health of its founder Donald Coar Dixon, and shrinking local markets. led to a slow and inevitable decline. The site is now vacant land.[10]

Hemmant Tannery c1980s. Image courtesy of Douglas Leighton Kesteven.

Lost Industries

Lost Heritage: A country's heritage is all the qualities, traditions, or features of life there that have continued over many years and have been passed on from one generation to another

Endangered Crafts/Trades: Traditional crafts and trades that are at risk of dying out in the succeeding generation.

Deindustrialisation: The reduction of industrial activity or capacity in a region or economy.

The story of the tanneries of Brisbane is, in part, a story of lost heritage, lost trades, and deindstrialisation. There are many change factors throughout history. The story of the rise – and decline – of the skin trades in Brisbane demonstrates the historical shifts in a sector of the local economy; in local work practices; local cultural shifts; the introduction of new technologies; as well as governance responses and initiatives generated around these shifts. From the early twentieth century these pioneering skin industries were subjected to a raft of pressures. The Dixon factories in West End and Hemmant – as were many others –– were experiencing mounting difficulties. By the 1970s Australian tanneries in general were hit by loss of tariff protection and subsequent cheap imports; encroaching urbanisation meant that tanneries that started up in locations some distance from residential development were increasingly under attack as ‘obnoxious, smelly neighbours’ and associated with that were increasing legislative requirements in respect to environmental pollution, especially water pollution; the introduction of cheaper synthetic options to leather; and for many, the need for urgent and expensive update of technologies.

Tanneries, like their partners in the ‘skin trades’. were not only becoming ‘problems’ (pollution, loss of markets etc.) but losing relevance (competitive products). These industries had serviced a pioneering rural economy, had provided goods and services for a colony in its early years; had given gainful employment to several generations of workers; and had skilled those workers not only in specific trades but had introduced them to an industrial and increasingly, industrialised world. Importantly, these industries had played an important role in developing the colony’s (and later state’s) economy. The historical records illustrate these achievements as we acknowledge the ongoing relevance, and value, of leather producers and their products.

Hide,Skin and Leather Products. Image courtesy of Dr. Robin Trotter.

Read part 1 of this blog - The Pioneering Hide, Skin and Leather Industries of Brisbane: Tanneries of Greater Brisbane [Part 1]

Dr Robin Trotter

Refereneces

[1] The story of Joseph Dixon has been told elsewhere – see Lindsell, Hessie & H. Lindsell, eds, 2006, Joseph Dixon: Buderim & Flaxton, 1870-2006, Buderim, Qld.

[2] Dixon, T C, 1908, transcript of talk presented at the opening of T C Dixon & Sons Boot Factory (courtesy Jocelyn Dixon, original held by Queensland Historical Society).

[3] England, M & Toowong History Group, 2008, From boots to ballet shoes: the Thomas Dixon Centre celebrating 100 years in 2008, Brisbane, Qld, Public Works.

[4] Dixon, T C, op.cit.; Aldine, Vol. 11, 1888; Brisbane City Council, Heritage Register; England, M & Toowong Historical Society, op.cit.; Queenslander, 6 July 1878, p, 444.

[5] ‘T C Dixon & Sons’, 1931, Brisbane Courier, Saturday, 11 July, p.11.

[6] Packer, Lindsay, 2024, personal interview, 3 June.

[7] Dixon, T C. op.cit.

[8] Brisbane City Council, op. cit.

[9] Kesteven, D L, 2023, ‘Donald Dixon and the Hemmant Tannery’, unpublished manuscript.

[10] Kesteven, D L, op. cit.

Other blogs by Dr Robin Trotter, 2021 and 2024 Queensland Business Leaders Hall of Fame Fellow

- Bootmakers of Brisbane [Part 1]

- Bootmakers of Brisbane [Part 2]

- The Pioneering Hide, Skin and Leather Industries of Brisbane: The Dixon Tanneries [Part 1]

- Frank McDonnell And The Early Closing Movement

- How to make a Carton: history of paper making in Australia

- The making of a Knight: Sir Arthur Petfield

- A Career in Cards

- How Napoleon's pistols came to Queensland

- Sir Arthur Petfield and 'The World Shrinkers'

Dr Robin Trotter's Research Reveals talk.

Comments

Your email address will not be published.

We welcome relevant, respectful comments.