How to make a Carton: history of paper making in Australia

By Dr Robin Trotter, 2021 Queensland Business Leaders Hall Of Fame Fellow | 3 November 2022

How often do you use a carton? Nearly every day.

But how often do you think about cartons? Almost never, except when you throw them away.

Yes, cartons are always with us - they are essential in many ways – getting products to us, storage of products, conveying products – and then when separated from the products, disposing of them makes cartons a problem at the end of their use. Or are they?

So, let’s think about this humble household item in a little more depth.

Whilst cartons are an important element in any industry, carton manufacture is, itself, a major industry. According to a report on the global corrugated board packaging market, this industry was valued at USD 262.61 billion in 2019, and it is expected to reach USD 339.95 billion by 2025. And it is an industry that has many components.

The history if packaging is long. Firstly, the production of paper goes back to pre-history and precursors of paper such as: clay tablets, papyrus, parchment (prepared animal hide), fabric (e.g. silk). But ultimately, it appears that paper proper originated in China anytime between 25–220 CE. This paper was the product of treating various forms of plant based materials for their cellulose content and combined with water to produce a pulp that was then dried into sheets. Today, paper making is a streamlined process from the raw pulp to finished paper.

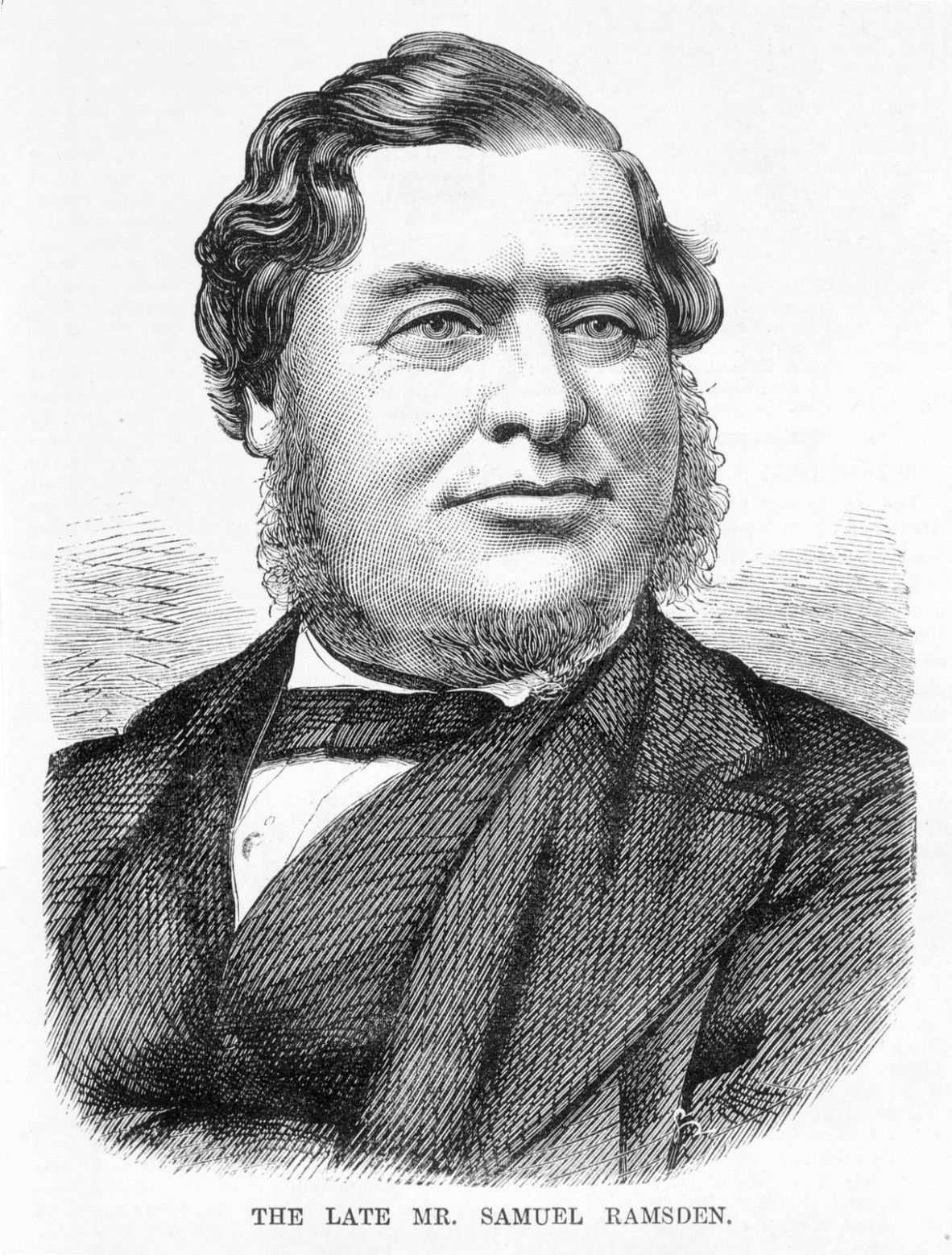

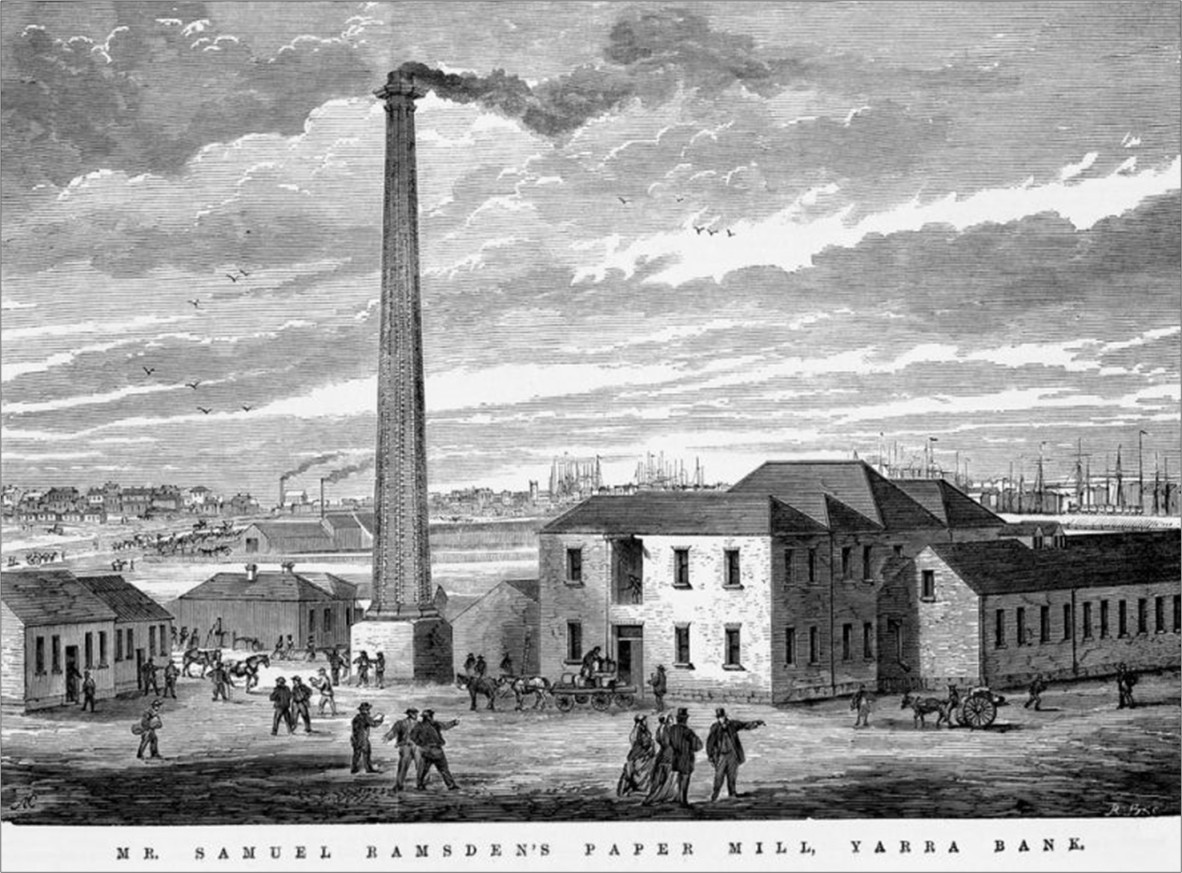

The history of paper making In Australia records that Samuel Ramsden succeeded in producing Victoria's first paper at his newly completed mill in 1868. On 4 May 1868 "The Evening Star" newspaper published an edition of 100 copies on the first hundred sheets of newsprint produced at Ramsden's mill.

Samuel Ramsden 1822-1877. Samuel Calvert (engraver), State Library of Victoria, Accession No : IAN21/03/77/40.

Papermaking in Victoria to 1900. Mr Samuel Ramsden Paper Mill, Yarra Bank, 1868. State Library of Victoria, Robert Bruce (engraver), Accession No : IAN25/04/68/5.

Among the early Australian pioneers into papermaking was the Australian Paper Mills Company Limited which was born in 1895 out of a merger of several paper makers in Victoria (A Spreading Tree, pp. 18-25). After a series of mergers, Australian Paper Manufacturers emerged in 1920 and operated from then until a change of name in 1996 to Amcor. The name change was implemented to represent the company’s diversification into a raft of industries. More recently this Australian based diversified multi-national operation has become part of the International paper company, Nippon Paper.

APM opened its Queensland operation with the Petrie Timber Mill starting up in 1957 and its pulp mill 1964.

Late 1950s Aerial Photograph Showing the Australian Paper Manufacturers (APM) Petrie Mill during the Final Stages of Construction (2008). Moreton Bay Regional Council, 2008. John Oxley Library, State Library of Queensland. Image number: pin0181.

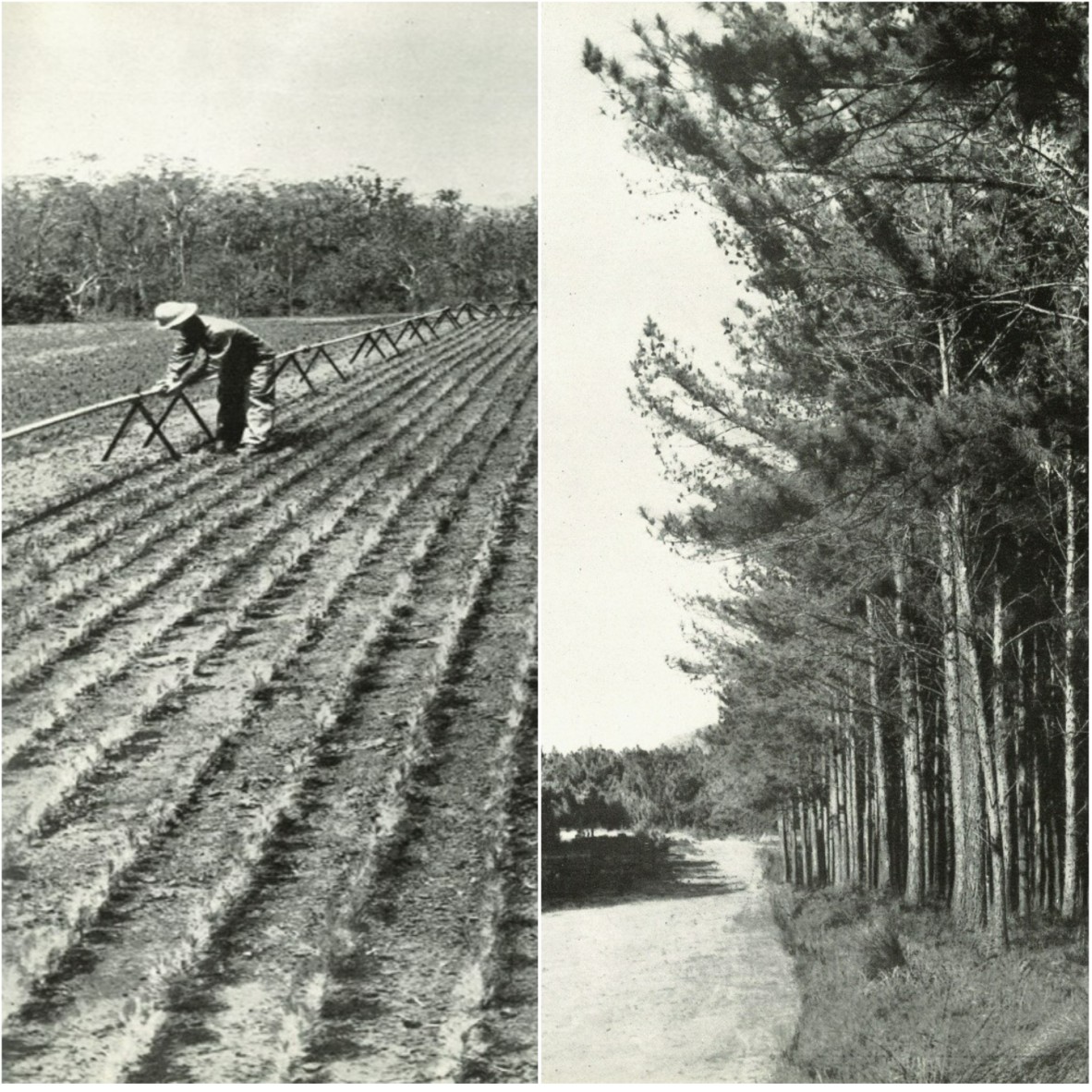

The base raw material starts in the forest or the plantation:

Australian Paper Manufacturers, 1957. To Remind you of your visit to the Inauguration Ceremony of the Petrie Mill, Australian Paper Manufacturers Ltd, Brisbane, 1957. John Oxley Library, State Library of Queensland.

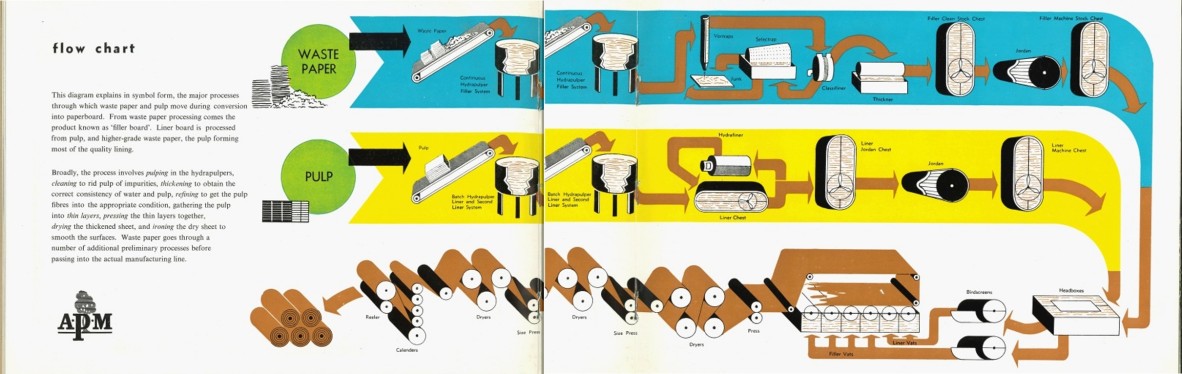

Flow Chart showing manufacturing process for paper. To Remind you of your visit to the Inauguration Ceremony of the Petrie Mill, Australian Paper Manufacturers Ltd, Brisbane, 1957. John Oxley Library, State Library of Queensland.

The finished paper – in large rolls - next goes through a converting operation to produce cardboard. Here is a delivery truck from APM arriving at the warehouse of Queensland Can Company (QCC), Vulture Street, West End, 1957.

The First AMP delivery of paper to Queensland Can Co. Ltd, 1957. Moreton Bay Regional Libraries, Reference number ITEM000688.

QCC, which started up manufacturing cans from tinplate in 1921 later moved into producing labels for cans and small cartons and, in 1947, made a major expansion into the manufacture of fibreboard cartons. Initially, QCC produced cartons from solid fibre cardboard but by 1952 the company had assembled a corrugating machine to produce corrugated board for forming into corrugated cartons.

QCC factory, Hamilton road, Moorooka, c.1947. 27449 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

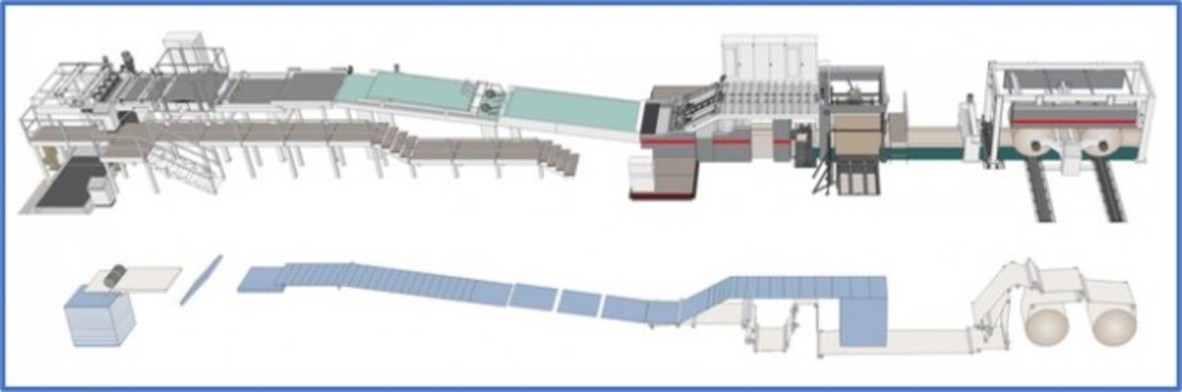

Machinery to manufacture a corrugated carton starts with the corrugator but then goes through a number of other machines to produce the finished carton:

For the technical minded, this diagram illustrates the processes incorporated into a corrugator;

Corrugator Machine-Corrugated Board Making Machine. Source: https://corrugated-box-printing-machine.pr.co/120057-corrugator-machine-corrugated-board-making-machine

The corrugator machine is the largest and most expensive machine in the corrugated fibreboard manufacturing process. It is about the length of a football field and can cost several million dollars. It is made up of a series of smaller machines that linked together combine two different kinds of paper to create cut sheets of corrugated fibreboard. The flat, facing sheets are referred to as the liners, and the wave-like, fluted layers are known as the corrugating medium, or simply medium. The corrugator takes large rolls of paper, flutes the medium and glues it to the liners, one at a time, and delivers stacked, cut, and scored sheets of corrugated board to various converting machines. The converting machines convert the sheets of corrugated board into “box blanks,” which are ready to be made into boxes, and other corrugated board products.

Modern corrugators can also be equipped with innovative enhancements that offer a range of value added features such as functional coatings, color coating, tear tape or internal strings, and water resistant adhesives.

There are other items of equipment used in the manufacture of our corrugated fibreboard carton such as:

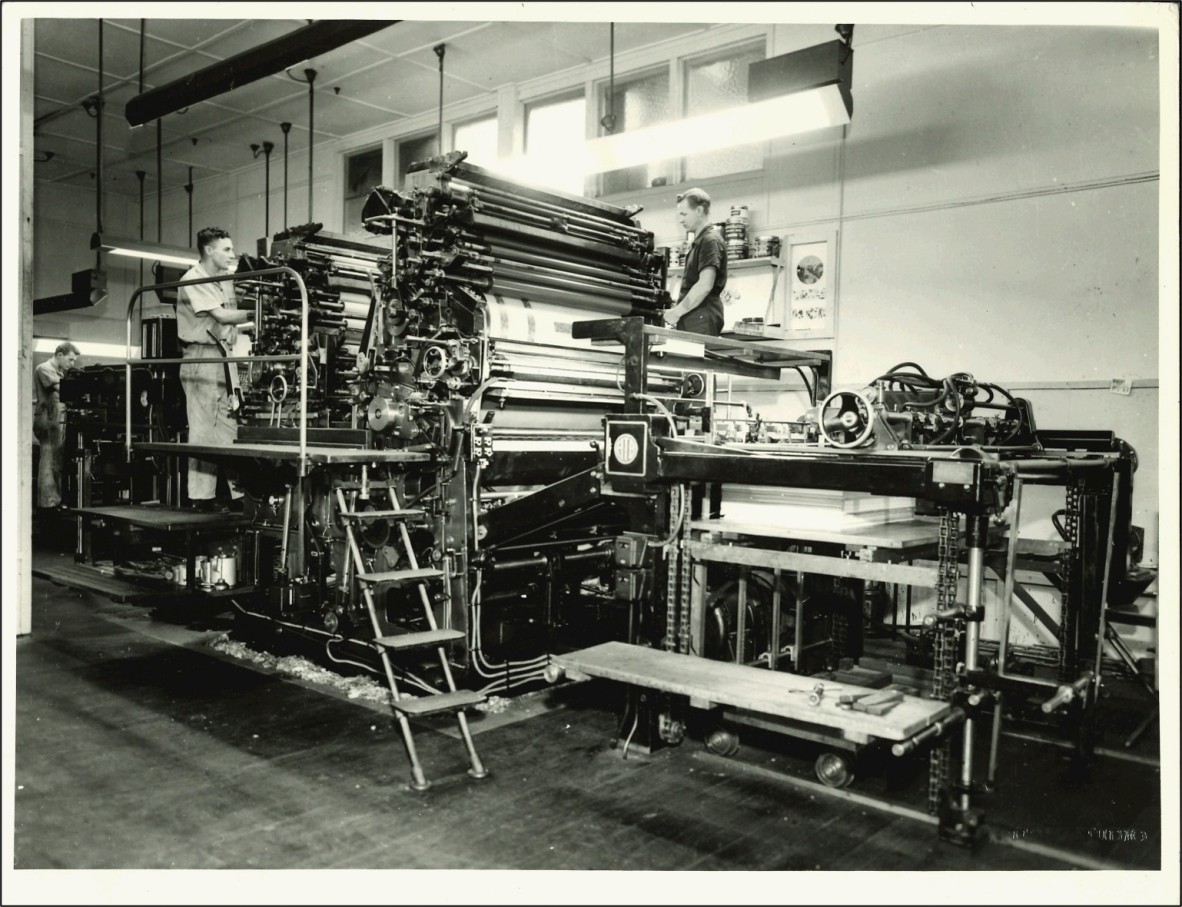

An offset flexographic printer, or flexo printer. This printing process involves the transfer of inks from a plate to rubber or metal stereos and then from the stereo to the board.

Offset Litho Printer, QCC factory, Hamilton Road, Moorooka, Qld. 1953. Warren, J., n.d., A Story of Queensland Can Company/United Packages Limited 1991 – 1982, Amcor Fibre Packaging, Rocklea, Qld. John Oxley Library, State Library of Queensland.

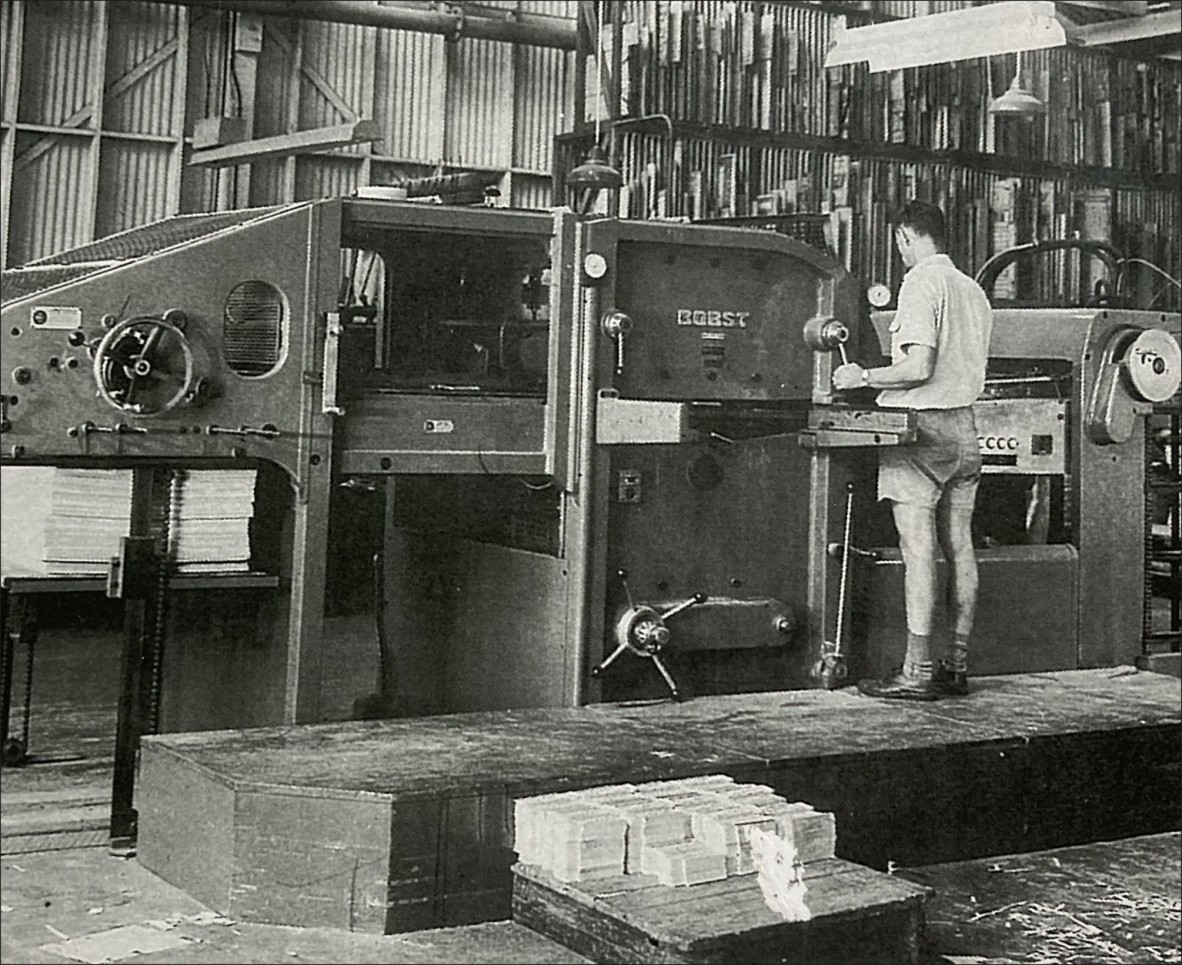

A die cutter. This machine cuts the sheets of corrugated fibreboard into appropriate size for the specified carton.

Bobst Die Cutter, QCC factory, Hamilton Road, Moorooka, Qld. 1955. Warren, J., n.d., A Story of Queensland Can Company/United Packages Limited 1991 – 1982, Amcor Fibre Packaging, Rocklea, Qld. John Oxley Library, State Library of Queensland.

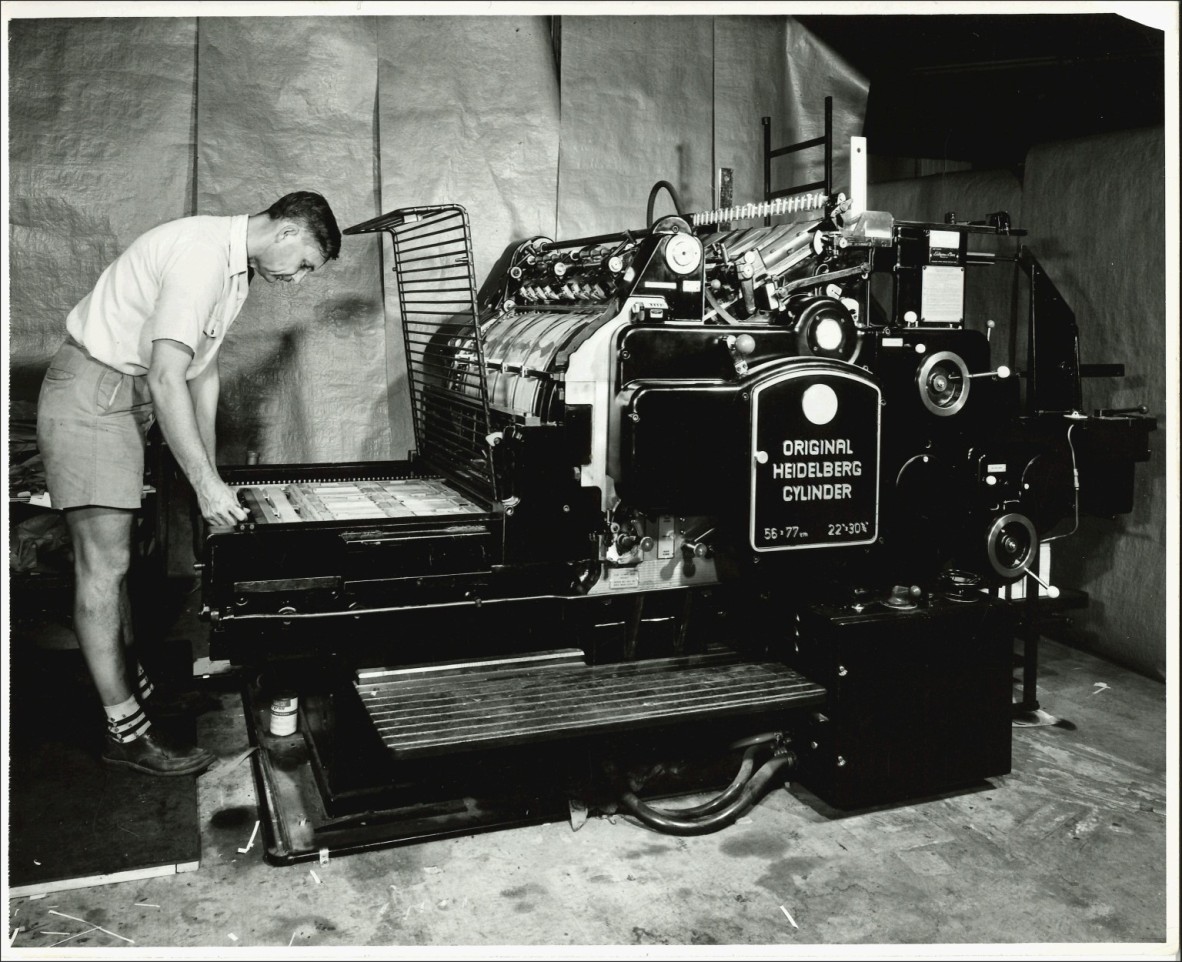

A Printer for printing of our carton:

Heidelberg Cylinder Press, QCC, Moorooka, 1953. Warren, J., n.d., A Story of Queensland Can Company/United Packages Limited 1991 – 1982, Amcor Fibre Packaging, Rocklea, Qld. John Oxley Library, State Library of Queensland.

A Gluer to add glue to the carton.

Employees working on the Staude Carton Gluer, QCC, Moorooka factory, 1955. Warren, J., n.d., A Story of Queensland Can Company/United Packages Limited 1991 – 1982, Amcor Fibre Packaging, Rocklea, Qld. John Oxley Library, State Library of Queensland.

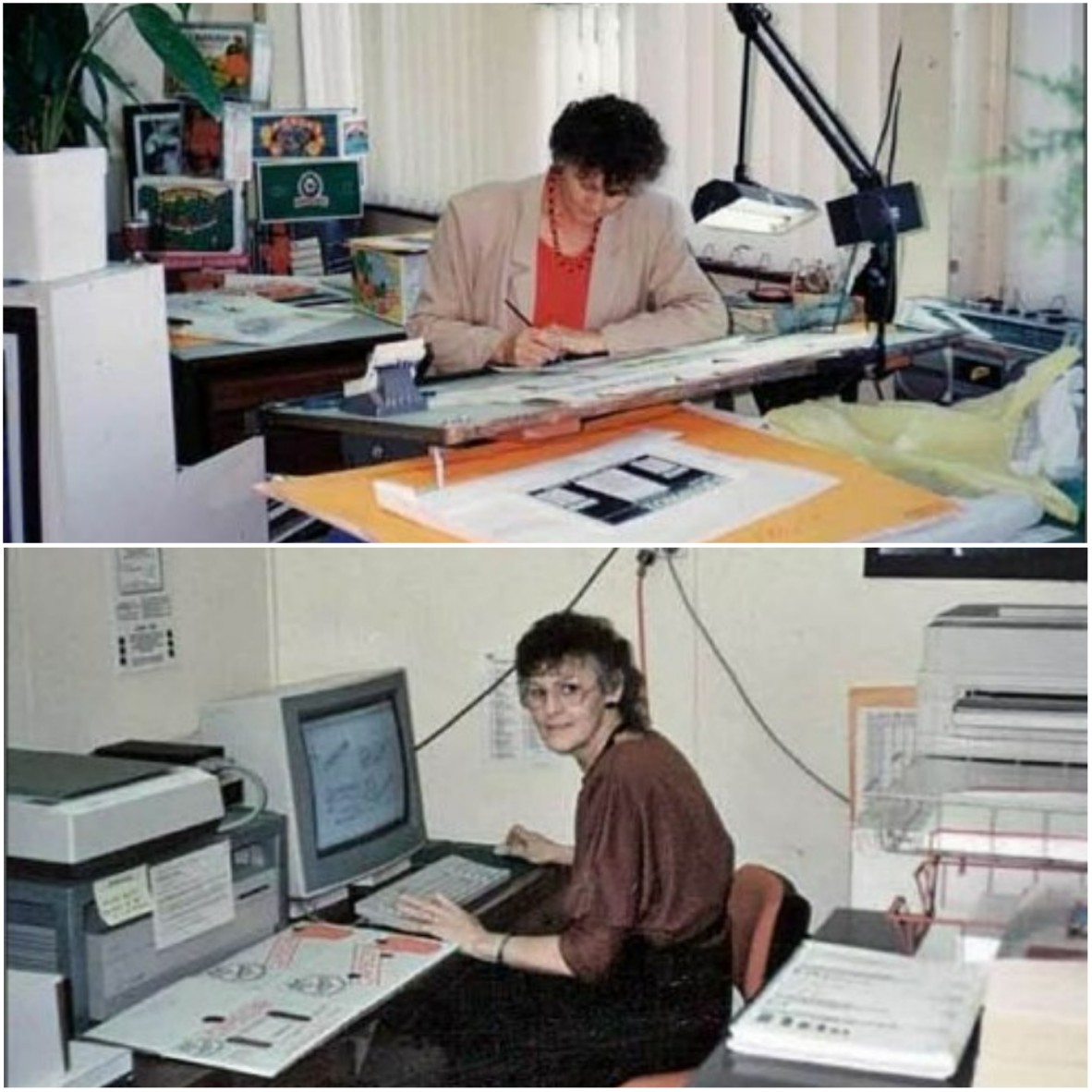

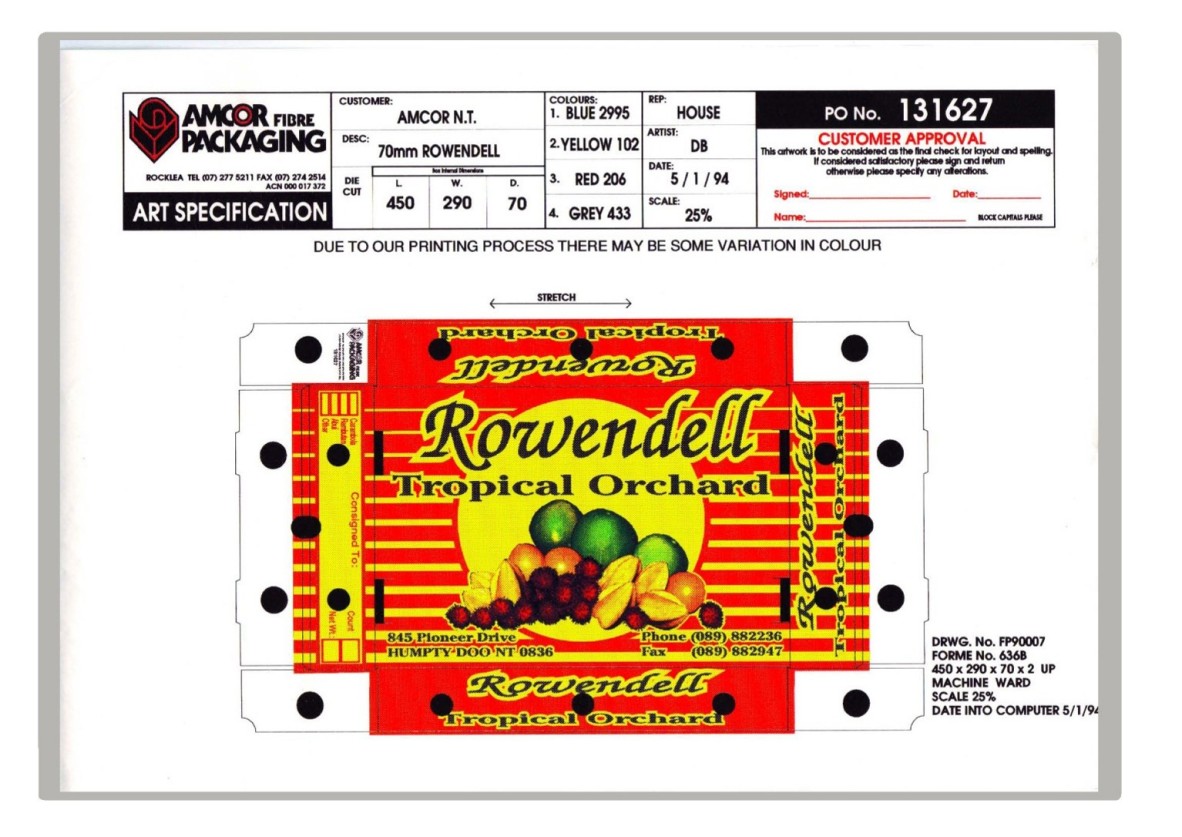

For our carton to show the contents and other vital information about the contents, it needs high quality art work to add the important finishing touches. So an art department is a critical component of the fibreboard carton production process. At QCC the art department at the outset served both the can making and the carton making sides of the operation. However, there was a separation of the two sides of the operations as the company expanded and as new technologies emerged in the two areas, and also as art departments moved from manual to computer generated technologies – as an ex-Art Department staff member put it – art design moved ‘from hand to mouse’ (Burgaty, 2008).

QCC Art Deptment – Dawn Burgary, c.1990 (top) 1991 (bottom). Computer designed art work. 27449 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

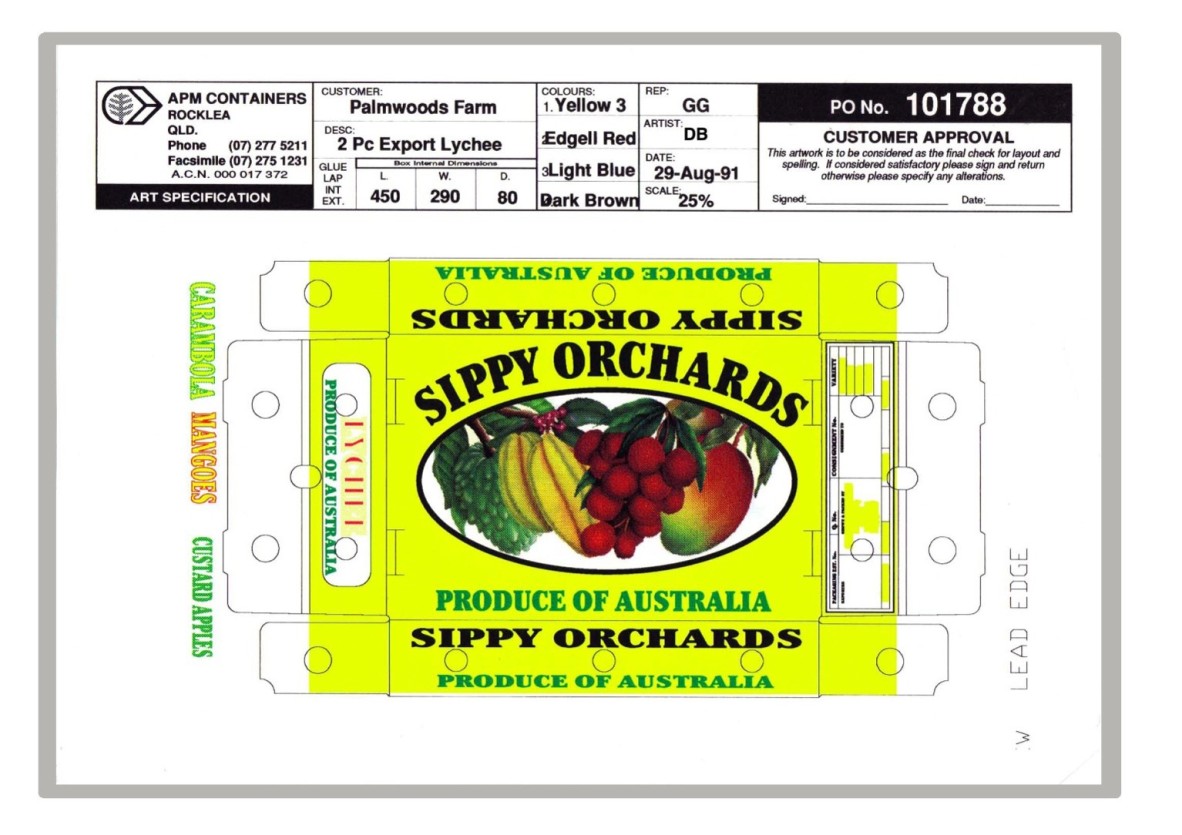

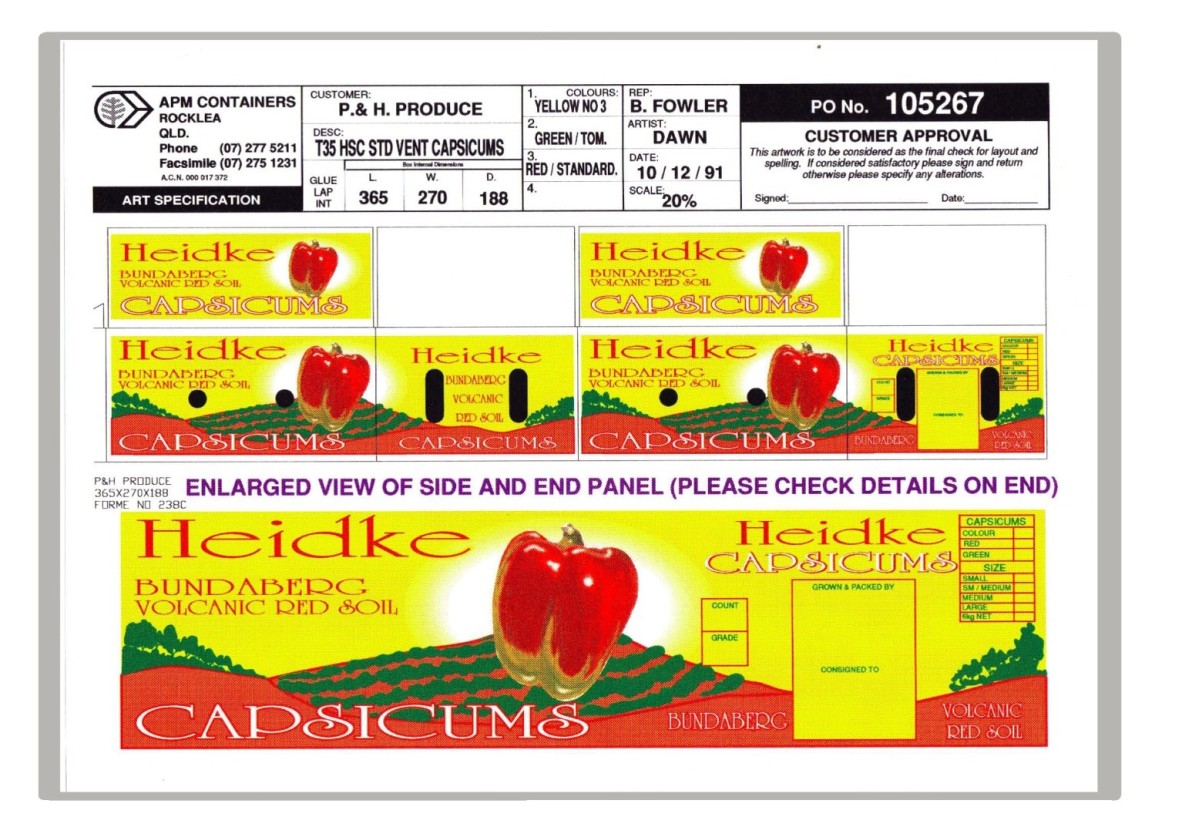

The designs on cartons are not only ‘selling’ the contents but also providing information about the product. The connection between art and product can also have historical and social significance. As cartonographer, Sean Rafferty, comments in relation to the humble fruit carton, it is ‘a kind of vernacular marker’ (private document CARTONS – 22 – 25). Let’s see how this works with sample carton designs from Amcor:

QCC Art Deptment – Dawn Burgary, c.1991. Computer designed art work. Burgaty, Dawn, and Amcor Limited. 27499 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

QCC Art Deptment – Dawn Burgary, c.1991. Computer designed art work. 27499 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

QCC Art Deptment – Dawn Burgary, c.1991. Computer designed art work. Burgaty, Dawn, and Amcor Limited. 27499 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

This story has touched briefly on the history of paper making in Australia, the processes involved in the production of the humble cardboard carton, and has drawn on the collections of the State Library of Queensland for many of the images. So, give a thought to the history behind your carton and ensure that when your carton has done its job, please consign it to the recycling bin so that it can be re-used in the production of recycled pulp for future cartons. |And also give a thought to your carton’s life cycle, to the work and technologies involved in its production, and to the intrinsic and cultural values embedded in such a prosaic item.

Dr Robin Trotter

The Queensland Business Leaders Hall of Fame is an initiative of QUT Business School, State Library of Queensland and the Queensland Library Foundation.

References

- Australian Paper Manufacturers, 1957, To Remind you of your visit to the Inauguration Ceremony of the Petrie Mill, Australian Paper Manufacturers Ltd, Brisbane.

- Burgaty, Dawn, and Amcor Limited. 27499 Amcor Art Department Records 1958-2008, John Oxley Library, State Library of Queensland.

- Global Corrugated Board Packagoing Market: Size, Growth, Trends and Forecasts (2020—2025)

- Samuel Ramsden, Collingwood Historical Society.

- Sinclair, E.K., 1990, The Spreading Tree: A history of APM and AMCOR 1844-1989, Allen & Unwin, 1990.

- Warren, J., n.d., A Story of Queensland Can Company/United Packages Limited 1921-1982, Amcor Fibre Packaging, Rocklea, Queensland.

Other blogs by Robin Trotter

Comments

Your email address will not be published.

We welcome relevant, respectful comments.