A history of some mines of the Biggenden District

By Guest blogger: David Huggonson | 19 February 2021

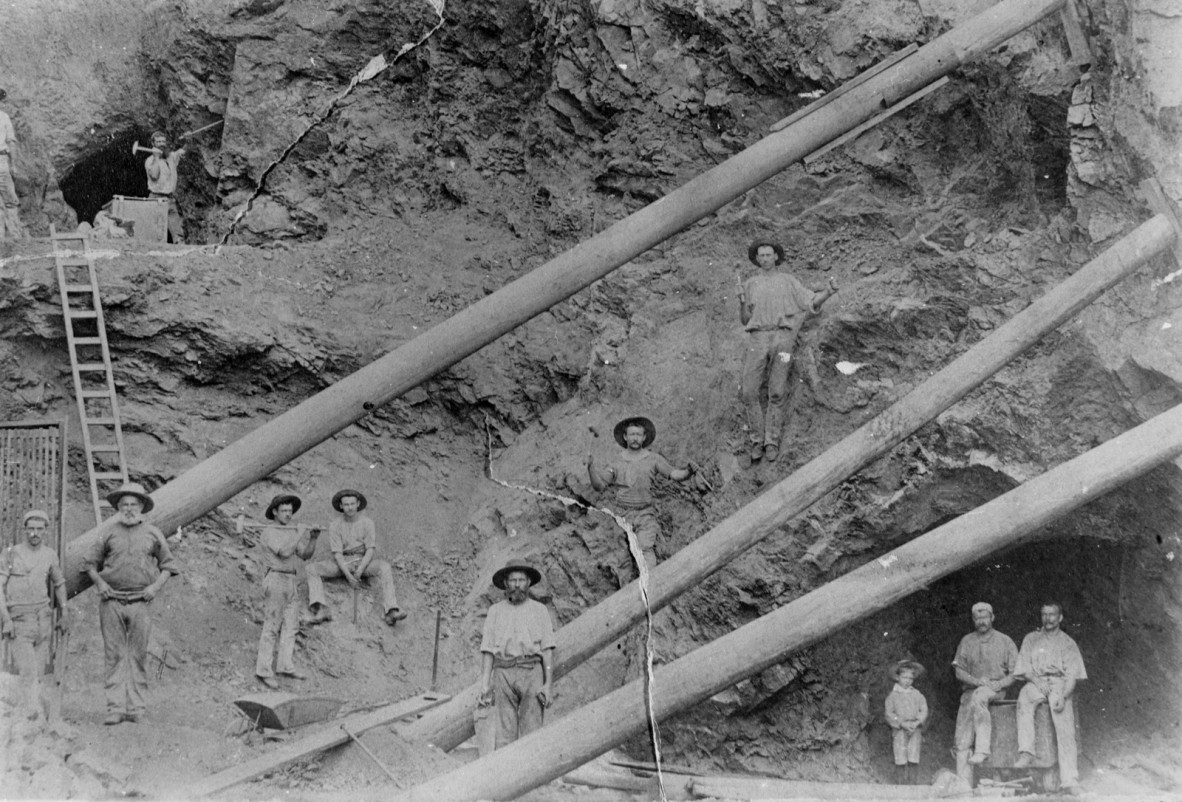

Bismuth mine and miners in the Biggenden region, ca. 1890. John Oxley Library, State Library of Queensland. Image number: 21603

Guest blogger: David Huggonson

The Mt Biggenden mine provided employment to the local community for over a hundred years, before its magnetite iron ore operation closed in 1999. The mine is located just 4km from the township with an access road branching off the Isis Highway.

Under the Griffith Government’s 1884 Lands Act, leased pastoral stations were divided into two portions as a way of unlocking land and making it available for closer settlements. The pastoralist retained one half, under a leasehold arrangement and the other half reverted to the crown for closer settlement. Thus the government’s Maryborough Land Agent opened eastern half of the former Degilbo run for agricultural settlement.

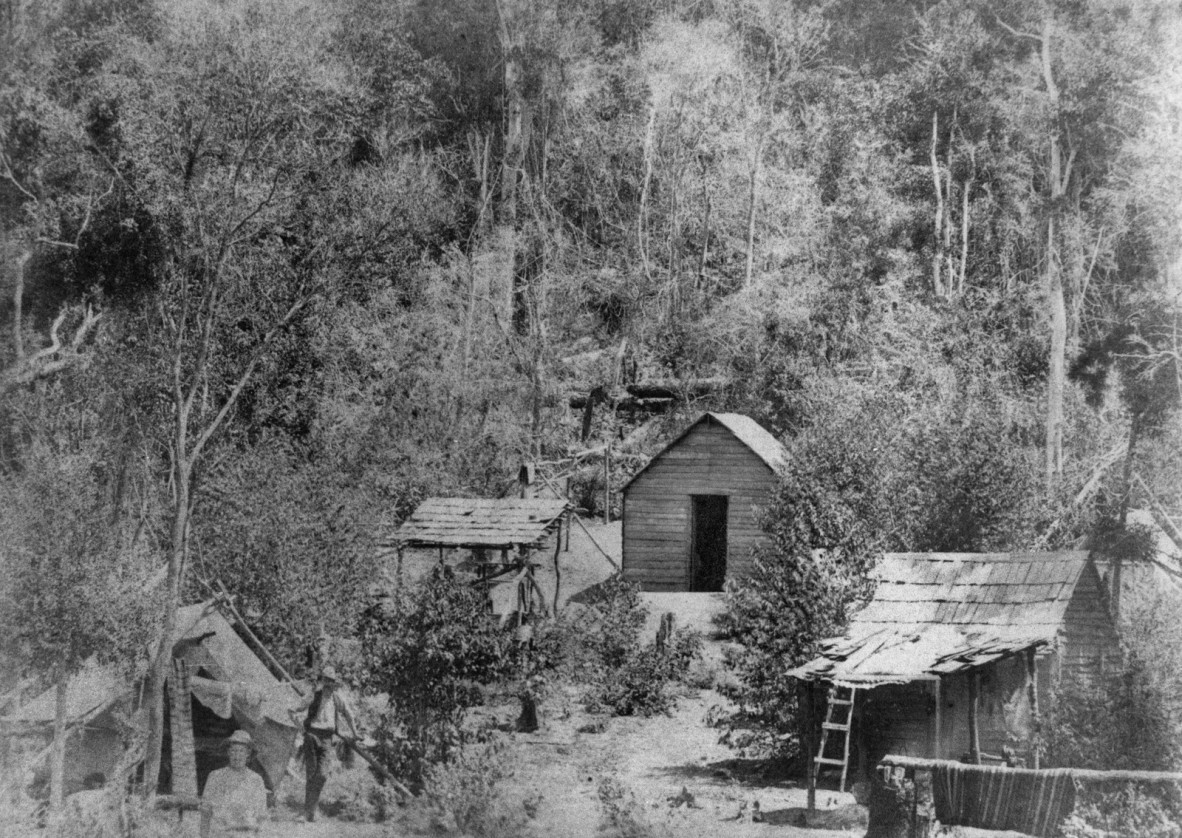

Miners on Mount Biggenden, ca. 1890. John Oxley Library, State Library of Queensland. Negative number: 142128

John Jensen reported iron ore deposits at Mt Biggenden in 1887 but richer minerals induced a Maryborough Company to start mining operations in 1890 for gold and bismuth. Mr W B Roberts, an experienced Gympie miner, was hired to manage the mine from the beginning of the company’s operations. Mr John H Pryce of Pryce and Anderson of Maryborough was the company’s secretary. Pryce and Anderson was a firm of accountants and general agents with offices in Wharf Street, Maryborough.

In 1889, construction began on a railway extension from Mungar on the Gympie to Maryborough line to the Burnett region. On 13 May 1891 a new railhead was opened and the brand new township named Biggenden was surveyed. The railhead was named after Mt Biggenden. A public auction was held in Maryborough on 29 September 1891 for town allotments. The enterprising publican, Samuel Baxter, lost no time in relocating his “Live and Let Live” hotel from a location near the Degilbo creek road crossing to the corner of Edward and Victoria Streets across from the new railway station; other businesses soon followed. The railway encouraged more selectors to take up agricultural farms in the Degilbo/Biggenden District but many needed to work in mines, the timber industry or on road construction to provide for their families, and to purchase stock and farming equipment.

The railway reduced the cost of shipping ore in thick canvas bags to the Port of Maryborough. For example most of Mt Biggenden’s bismuth was shipped to Sydney. Mt Biggenden Mine operated intermittently between 1890 and 1912 and most gold was mined underground in this period. The “Brisbane Telegraph” reported on 24 December 1890 that a small Jiga ore-crushing mill was in use and 96 tons of ore was crushed resulting in 107 ounces of smelted gold.

Besides gold, from 1888 until 1915, Mt Biggenden Mine produced 50% of Queensland’s bismuth, which is a medicinal ingredient used to treat upset stomach, heartburn and nausea. It is also used to treat diarrhoea by helping to slow the growth of bacteria that might cause diarrhoea. During most of this period the mine was worked by a German Syndicate but under the Commonwealth’s War Precautions Acts and the Trading with the Enemy Acts ownership was forfeited and the mine ceased operations for almost twenty years. Of course, the worldwide depression of 1929-33 did not help matters.

In 1933, Bismuth Products Ltd purchased the Mt Biggenden mine. The Sydney Drug Company invested 30,000 pounds to update the mine and created employment for 30 men. The “Maryborough Chronicle” of 8 September 1934 reported on a tour of inspection by business men connected to the company. They expressed satisfaction with the amount of bismuth, gold and other minerals being produced by the mine. The company installed a pipeline to Degilbo Creek and pumped water to a storage tank at the top their mill for use of the boiler and mill. A steam-driven Bellis and Morgas ball mill crushed the ore on site. The mill contains about six ton of steel balls, which are revolved in a steel cylinder 25 times per minute. The fine powder produced was then transported by rubber belt system to floatation boxes. The concentrates are dried by steam pipes then sealed in 44-gallon drums and sent to Sydney. By October 1934 the company was campaigning for local government to construct a good all-weather road from the mine to the Biggenden railhead. The company stated that they were carting 100 tons of minerals each week and that a two-mile stretch of black soil made the road impassable in wet weather. There were also five creek crossings on the old road. The Company carried on mining bismuth until 1967 when operations ceased due to the low price for bismuth.

During October 1941 an attempt was made to interest Mr Essington Lewis, who was the Coordinator of the Commonwealth War Industries, to mine the neglected magnetite, (iron oxide) located at Mt Biggenden. At the time Australia only had two high-grade iron ore bodies, Yampi Sound in Western Australia and Iron Knob in South Australia. Because of the massive beneficiation required before magnetite would be saleable to the steel making industry, nothing came of the attempt, even though it had been known since John Jensen’s original discovery that a large deposit of iron oxide existed at Mt Biggenden.

The Commonwealth Government’s long-standing embargo on the export of iron ore was finally lifted in December 1960. Lang Hancock of the Pilbara region of West Australia struggled for years to have the State and Commonwealth Governments realise the enormous export potential of the vast deposits of high grade iron ore with low silica content in the Hamersley Ranges. Hancock managed to interest Rio Tinto Company of London, Kaiser Steel Corporation in the United States of America and Consolidated Zinc Pty Ltd in financing the project. Today the million of tons of Pilbara iron ore after only crushing is direct shipped to China, Japan and South Korea. It is the major export earner for Australia.

But it was not in the steel making process that the magnetite from Biggenden mine was used. Dutch researchers had discovered the usefulness of magnetite as an agent in the coal washing process as early as 1912. The coal beneficiation processes is where inorganic impurities are separated from raw mined coal thereby enhancing the combustion characteristic of the coking coal. When finely milled magnetite is suspended in water in cyclones and spirals it produces a dense medium suitable for separating impurities from coal. The denser magnetite is easily recovered once it sinks to the bottom of the tank by applying a magnetic field.

The Biggenden economy was in decline in the mid 1960s after the closure of its butter factory and sawmill, fortunately the demand for magnetite increased with the boom in Australian coal exports to Asia. This led to Commercial Minerals Limited opening and operating an open-cut mine at Mt Biggenden from 1967 until 1999. During this time 800,000 tonnes of refined magnetite was produced and sent to coal washing plants in the Hunter Valley, Ipswich, Blackwater, and Moura.

The access road to Biggenden mine was finally re-routed, and an all-weather road constructed and sealed in 1971. Mr Clarrie Harvey, a long-term employee of the trucking firm says before the new road was built many truck tires were shredded during the old creek crossings because of sharp stones at the fords. The mine ceased operation in 1999 except for gravel extraction.

Teacher and children from Biggenden Mines State School, ca. 1906. C.H. Powell, John Oxley Library, State Library of Queensland. Negative number: 38931

The railway reduced the cost of shipping ore in thick canvas bags to the Port of Maryborough. For example most of Mt Biggenden’s bismuth was shipped to Sydney. Mt Biggenden Mine operated intermittently between 1890 and 1912 and most gold was mined underground in this period. The “Brisbane Telegraph” reported on 24 December 1890 that a small Jiga ore-crushing mill was in use and 96 tons of ore was crushed resulting in 107 ounces of smelted gold.

Besides gold, from 1888 until 1915, Mt Biggenden Mine produced 50% of Queensland’s bismuth, which is a medicinal ingredient used to treat upset stomach, heartburn and nausea. It is also used to treat diarrhoea by helping to slow the growth of bacteria that might cause diarrhoea. During most of this period the mine was worked by a German Syndicate but under the Commonwealth’s War Precautions Acts and the Trading with the Enemy Acts ownership was forfeited and the mine ceased operations for almost twenty years. Of course, the worldwide depression of 1929-33 did not help matters.

In 1933, Bismuth Products Ltd purchased the Mt Biggenden mine. The Sydney Drug Company invested 30,000 pounds to update the mine and created employment for 30 men. The “Maryborough Chronicle” of 8 September 1934 reported on a tour of inspection by business men connected to the company. They expressed satisfaction with the amount of bismuth, gold and other minerals being produced by the mine. The company installed a pipeline to Degilbo Creek and pumped water to a storage tank at the top their mill for use of the boiler and mill. A steam-driven Bellis and Morgas ball mill crushed the ore on site. The mill contains about six ton of steel balls, which are revolved in a steel cylinder 25 times per minute. The fine powder produced was then transported by rubber belt system to floatation boxes. The concentrates are dried by steam pipes then sealed in 44-gallon drums and sent to Sydney. By October 1934 the company was campaigning for local government to construct a good all-weather road from the mine to the Biggenden railhead. The company stated that they were carting 100 tons of minerals each week and that a two-mile stretch of black soil made the road impassable in wet weather. There were also five creek crossings on the old road. The Company carried on mining bismuth until 1967 when operations ceased due to the low price for bismuth.

During October 1941 an attempt was made to interest Mr Essington Lewis, who was the Coordinator of the Commonwealth War Industries, to mine the neglected magnetite, (iron oxide) located at Mt Biggenden. At the time Australia only had two high-grade iron ore bodies, Yampi Sound in Western Australia and Iron Knob in South Australia. Because of the massive beneficiation required before magnetite would be saleable to the steel making industry, nothing came of the attempt, even though it had been known since John Jensen’s original discovery that a large deposit of iron oxide existed at Mt Biggenden.

The Commonwealth Government’s long-standing embargo on the export of iron ore was finally lifted in December 1960. Lang Hancock of the Pilbara region of West Australia struggled for years to have the State and Commonwealth Governments realise the enormous export potential of the vast deposits of high grade iron ore with low silica content in the Hamersley Ranges. Hancock managed to interest Rio Tinto Company of London, Kaiser Steel Corporation in the United States of America and Consolidated Zinc Pty Ltd in financing the project. Today the million of tons of Pilbara iron ore after only crushing is direct shipped to China, Japan and South Korea. It is the major export earner for Australia.

But it was not in the steel making process that the magnetite from Biggenden mine was used. Dutch researchers had discovered the usefulness of magnetite as an agent in the coal washing process as early as 1912. The coal beneficiation processes is where inorganic impurities are separated from raw mined coal thereby enhancing the combustion characteristic of the coking coal. When finely milled magnetite is suspended in water in cyclones and spirals it produces a dense medium suitable for separating impurities from coal. The denser magnetite is easily recovered once it sinks to the bottom of the tank by applying a magnetic field.

The Biggenden economy was in decline in the mid 1960s after the closure of its butter factory and sawmill, fortunately the demand for magnetite increased with the boom in Australian coal exports to Asia. This led to Commercial Minerals Limited opening and operating an open-cut mine at Mt Biggenden from 1967 until 1999. During this time 800,000 tonnes of refined magnetite was produced and sent to coal washing plants in the Hunter Valley, Ipswich, Blackwater, and Moura.

The access road to Biggenden mine was finally re-routed, and an all-weather road constructed and sealed in 1971. Mr Clarrie Harvey, a long-term employee of the trucking firm says before the new road was built many truck tires were shredded during the old creek crossings because of sharp stones at the fords. The mine ceased operation in 1999 except for gravel extraction.

David Huggonson

You can browse State Library's digitised collection of Biggenden photographs via our One Search catalogue.

Read other blogs by David Huggonson.

Comments

Your email address will not be published.

We welcome relevant, respectful comments.